Our Exothermic Welding Kit provides a comprehensive solution for creating robust and long-lasting electrical connections. Whether you're in telecommunications, power distribution, or grounding systems, this kit simplifies the process, ensuring durable, low-resistance joints. Say goodbye to unreliable connections and hello to superior performance with our Exothermic Welding Kit.

know more

Exothermic welding excels at creating various joints, including cable-to-cable, cable-to-rod, cable-to-steel, and more. These joints ensure durable, low-resistance connections, vital in industries like telecommunications, electrical, and grounding systems. Discover the versatility and strength of exothermic welding for your common joint needs.

know more

Exothermic welding is a transformative process, uniting metal components with extreme heat generated by a chemical reaction. This fusion creates enduring, low-resistance connections, essential in sectors like power distribution, telecommunications, and grounding systems. Explore the science and artistry behind exothermic welding, a method trusted for its robust, long-lasting results.

know moreExothermic welding, also known as thermite welding, offers a range of benefits that make it a preferred choice in various industries. Here are the key advantages of using exothermic welding:

A rotary kiln, often used in thermite welding, is a specialized cylindrical furnace designed to reach high temperatures. In this process, it plays a crucial role in heating and fusing metals, allowing for a strong and durable bond between two pieces. Its controlled rotation ensures uniform heating, making it a reliable tool for thermite welding applications.

An automatic weigh batcher plays a pivotal role by precisely measuring and dispensing the essential components, like aluminum powder and iron oxide, in the exact proportions required for the thermite welding process. This ensures the consistency and integrity of welds in railway tracks.

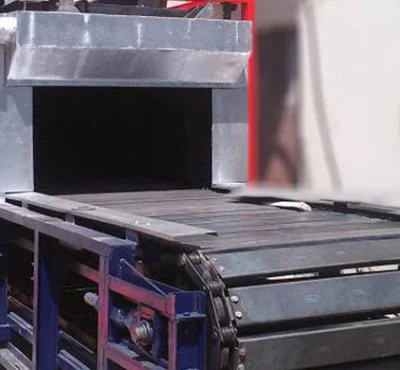

A fully automated slat conveyorized oven is an advanced system designed for baking dry molds, Single Shot Crucible(SSC), Multi Shot Crucible with an impressive daily capacity of 1000 units. This technology offers precision and efficiency in industrial operations, making it ideal for high-volume mold baking requirements. Its conveyorized design ensures smooth and consistent production, meeting the demands of various manufacturing processes.

Ultrasonic Flaw Detection is a valuable technique in thermite welding processes, ensuring the quality and integrity of rail and metal connections. By employing high-frequency sound waves to detect flaws or irregularities within the weld, it plays a crucial role in maintaining the safety and durability of thermite-welded joints. This method is essential for meeting stringent quality standards in rail and metalwork applications.

Magnetic Crack Detection Test is a crucial quality control step. It involves the use of specialized equipment to scan the welded area for potential cracks or defects that might have been introduced during the welding process. Identifying and addressing these issues promptly is essential for ensuring the structural integrity and safety of the rail track, making this test a vital component of post-welding inspection and maintenance procedures.

The Brinell Hardness Machine (3000 Kg) is a powerful and precise testing instrument used to measure the hardness of materials. With a testing force of 3000 kilograms. This machine provides reliable data for quality assurance and material selection, helping ensure the durability and performance of components and structures.

The Transverse Testing Machine, with a minimum capacity of 200 tons, is a critical tool used for inspecting the strength and stability of rail tracks after thermite welding. This testing ensures that the welded joints can withstand heavy loads and transverse forces, contributing to the safety and reliability of railway infrastructure. It plays a vital role in quality control and compliance with industry standards in rail track maintenance and construction.

A spectrometer is used to analyze the chemical composition of various metal. By measuring the element content, it ensures the quality and consistency of welds in railway tracks and other applications, crucial for maintaining the structural integrity and safety of rail infrastructure.

The microscope test is an essential quality control procedure. During this process, a sample from the welded joint is meticulously examined under a microscope to assess its microstructure. This examination provides critical insights into the integrity of the weld, including factors like grain size, grain boundaries, and any potential defects.

A Carbon Sulphur Determination Apparatus is a vital tool in laboratories for accurately measuring the carbon and sulfur content in various substances. This device utilizes high-temperature combustion to analyze the elemental composition, enabling researchers to assess the purity and quality of materials, making it indispensable for quality control and analytical chemistry in scientific settings.

A Water Distillation Plant is a crucial component in laboratory settings, providing high-purity water for experiments and analyses. It employs distillation techniques to remove impurities, ensuring that the water used in scientific research is of the highest quality and free from contaminants.

A Muffle Furnace, a common fixture in laboratories, is a high-temperature heating device used for processes such as ashing, burning, and heat treating. It ensures controlled and precise heating, making it invaluable for various scientific and analytical applications.

Essential equipment in laboratories, these ovens provide reliable and consistent heat for various scientific processes, including sterilization, drying, and testing, ensuring accurate results and safety.

Flasks are fundamental vessels in laboratory work, designed in various shapes and sizes to accommodate different experiments. They are essential for containing and mixing liquids, making them a cornerstone of scientific research and chemical processes.

Hot Plates are indispensable laboratory equipment, featuring a flat, heated surface for precise and controlled heating of glassware and samples. They are commonly used for tasks like heating solutions, evaporation, and maintaining consistent temperatures in experiments. Their versatility and reliability make them a staple in scientific research and chemical analysis.

Chemicals are the building blocks of scientific experiments in laboratories. They encompass a wide range of substances used for various purposes, from reagents for chemical reactions to solvents and indicators. Safety and proper handling are paramount when working with chemicals in the laboratory to ensure accurate results and protect researchers.

VMC is a precision tool for manufacturing, offering versatility in shaping and carving materials with utmost precision.

It’s used for production work of quick operation in general engineering workshops, automobile workshops, gauges etc. for driving mandrels in and out of work.

Lathes are the cornerstone of machining, expertly spinning and shaping materials to precise specifications.

Electrical furnaces harness electricity to generate high temperatures for industrial processes like metal smelting and heat treatment.

Surface grinders provide precision in achieving smooth and flat surfaces, critical in metalworking and engineering.

Sander machines smooth and finish surfaces, making them essential for woodworking and manufacturing.

Milling drill machines combine the capabilities of a milling machine and a drill press, facilitating precision drilling and machining in one unit.